Carbon monoxide basics

Carbon monoxide, also known as CO, is an odorless gas that is produced by fuel-fired equipment. If a furnace were to burn all of its available fuel, and I mean 100%, you’d have something called stoichiometric combustion. There would be no carbon monoxide generated, and no wasted fuel. In the real world, this is also called Theoretical Combustion, because it doesn’t happen. There’s always some amount of CO generated by a furnace, and that’s acceptable.

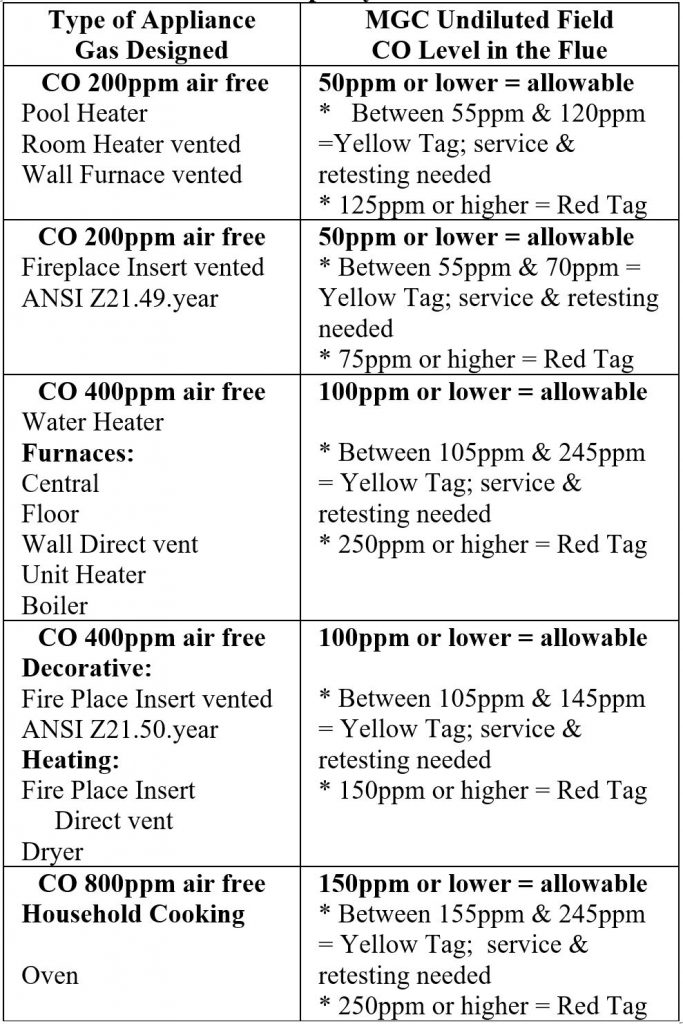

How much CO is acceptable?

If these standards are good enough for the gas company, they’re good enough for us.

When to test for CO

How long should a furnace run for before testing for CO? Fifteen minutes? Five minutes? I’ve heard numbers all over the board, but the most consistent answer I’ve heard, and the one that is referenced in the Minnesota State Fuel Gas Code (Chapter 9, Subp. 6) is to wait until “the stack temperature becomes stabilized”. In other words, wait until the temperature in the flue stops rising. Once the temperature has reached a steady state, you’re good to test. I’ve found this usually happens within about 5 minutes.

Source: https://structuretech.com/carbon-monoxide-testing-for-furnaces/